We Provide Best Industrial Services

Aluminum Alloys for Extrusion and Heat Treatment Processes

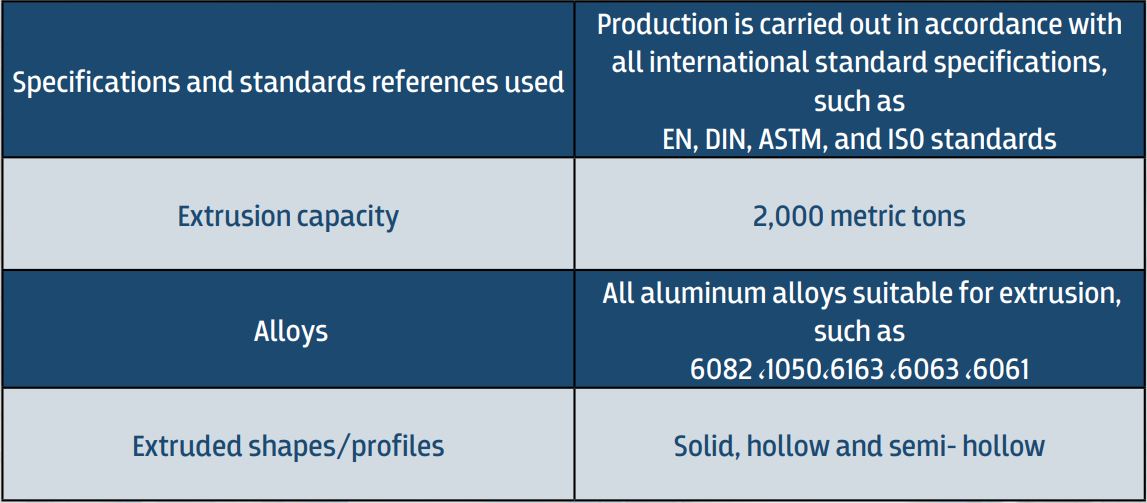

Eurotal Company produces all customers’s requirements of various aluminum alloys in its facilities, thanks to their excellent mechanical properties and high formability. Among these alloys, 6061, 6063, and 6082. These alloys are chosen according to customer requirements and in compliance with international standards.

Alloy 6061

• Properties: Characterized by high strength, good ductility, and corrosion resistance, in addition to its high weldability and machinability.

• Applications: Used in a wide range of products, such as window and door frames, structures, molds, and industrial components.

Alloy 6063

• Properties: One of the most common aluminum alloys, characterized by easy machinability, high malleability, and corrosion resistance.

• Applications: Widely used in the manufacturing of furniture, interior decorations, frames, and profiles.

Alloy 6082

• Properties: Characterized by high strength, excellent ductility, and good corrosion resistance, making it suitable for structural applications.

• Applications: Used in the construction of large structures such as bridges and towers, as well as in the manufacturing of vehicles.

Extrusion

Extrusion capabilities